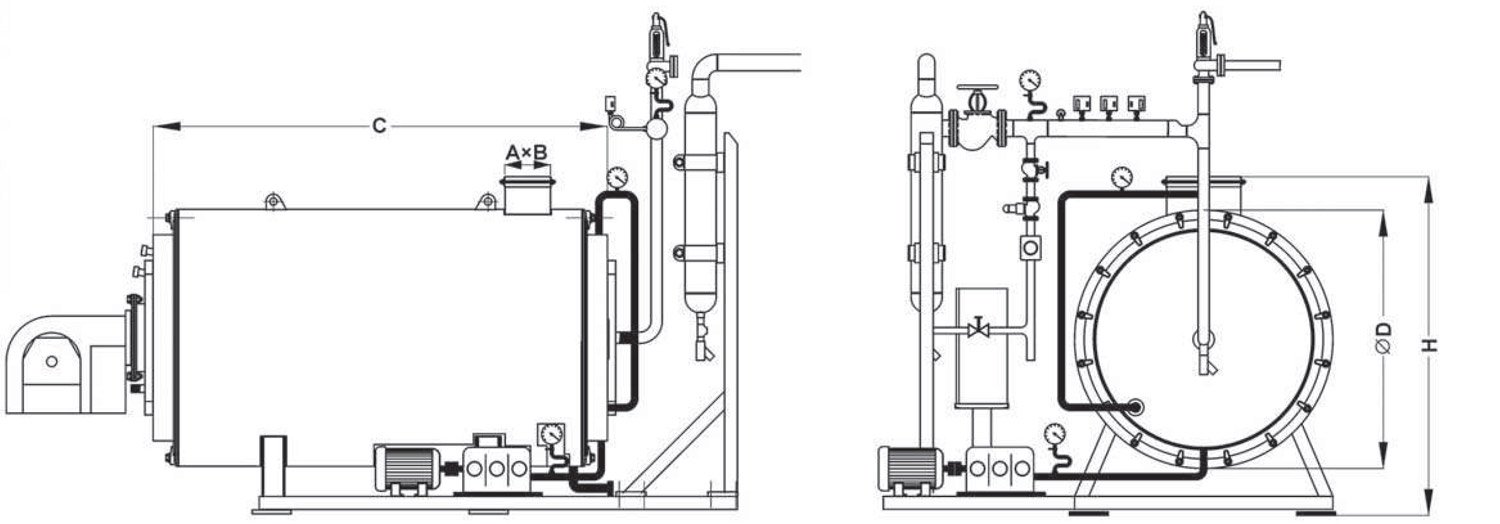

Watertube Horizontal Steam Boiler

Advantages and Features

- Quick Launch

- Optimal Efficiency up to 92%

- Equipped with an Economizer and Preheater

- Low Depreciation and Low Cost of Maintenance and Repairs

- Fully Automatic Control System

- Optimized Design with Minimal Space Required

- High Quality Materials and Consumables

- Automatic Disposal of Soluble Salts

The boiler controller system is designed full automatic and so it hardly needs an operator.

According to the particular design of body, the least amount of space is needed.

These boilers are designed in two different types: gravitational and pumping.

General Specifications

Capacity

400-5000 kg/hr

Work Pressure

10-100 bar

Designing

EN 12953

Fuel

Gas, Gasoline, Solid Fuels

Power Consumed

50 Hz - 380 V

Product Introduction

Daboo-Sanat by considering the new scientific achievements in the world and employing experts, started the design of these boilers in Iran.

Features:

- It is ready to work after passing just about 10 minutes from starting.

- Theses boilers are equipped by economizer and feed water pre heater. In addition, by using supplement equipment, efficiency increases to 92%.

- These kinds of boilers rarely need maintenance and in case of requiring it, all of pressure parts can be replaced at low cost and in the least amount of time.

- According to the special design of boilers, the significant amount of salt solution in feed water can be removed automatically.

- The boiler controller system is designed full automatic and so it hardly needs an operator.

- According to the particular design of body, the least amount of space is needed.

- High-quality substance and components used and, attention to the production levels besides the use of sophisticated equipment cause to high designed life.

- These boilers are designed in two different types: gravitational and pumping.

- These boilers with capacity of 400 – 5000 kg/h and admissible operation pressure of 10-100 bar are designed and produced.

- According to being water tube, the boiler improvement process, after passing its designed life, is done by the replacement of coils.

Steam boilers produced by Daboo-Sanat are designed based on EN 12953 standard and have a European validation certificate. Steel used in pressurized regions is A516G70 and DIN17155-17MN4 type, heat transfer tubes are fireproofing seam and DIN17175-ST35.8 type. Unpressurized regions are constructed from EN10025-S235JR.

The pressurized regions are welded by SAW approach automatically which result in the high quality welding and integrity. Heat transfer tubes are jointed to network by walls and welding. In addition, resistant tubes are jointed to network by electric arc welding based on WPS. Electrodes used for penetration and reinforcement welding are E 7010 and E 7018, which are based on WPS and PQR. AII of the weld beads are in accordance with national and international standards and are tested by inspectors of Iranian Standard and Research Agency. These tests include radiography, ultrasonic, penetrative materials and, hydrostatic, which are announced with technical certificate after the confirmation of quality inspections. All of the welders are examined based on EN287 test and have a welding license from high-accredited inspection centers. They are under the supervision of Quality Control Department of the Daboo-Sanat.

Each boiler is equipped by full automatic control panel, which is constructed from European high-grade components and includes security sensors.