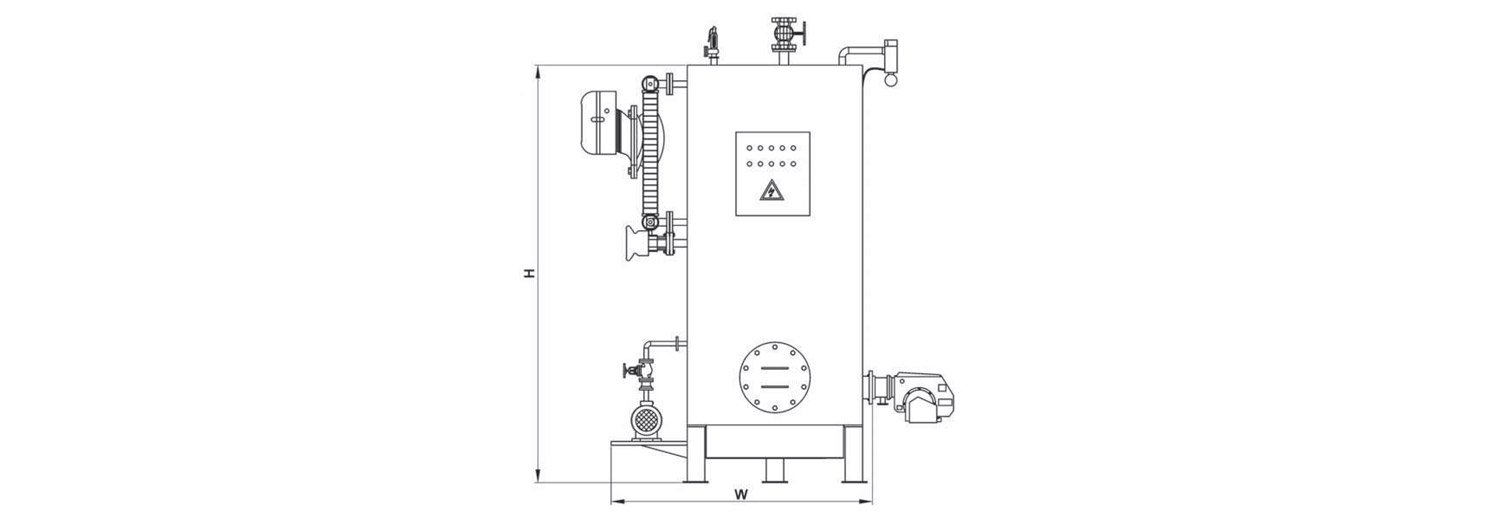

Vertical Steam Boiler

Advantages and Features

- High Efficiency

- Reduce Energy Consumption

- Increase The Heat Transfer Coefficient

- Equipped With Safety and Warning Systems

- Ability to Work with Natural Gas and Diesel Fuel

- Steel Blades for Reducing The Smoke Temperature

- Use of Spiral Pipes Instead of Horizontal and Vertical Pipes

The use of spiral tubes instead of horizontal and vertical tubes causes to increase in heat transfer coefficient.

All of the security equipment and warning system are set on this system.

Vertical boilers have the capability to run with national gas and gasoline.

General Specifications

Capacity

60-2000 Kg/hr

Work Pressure

6-8-10-15 bar

Designing

EN 12953

Fuel

Gas, Gasoline

Power Consumed

50 Hz - 380 V

Product Introduction

Features:

- This product has considerable efficiency of 90%.

- Vertical boilers are equipped by combustion preheater. By using this system, combustion process. The reduction of energy consumption and, high efficiency.

- The use of spiral tubes instead of horizontal and vertical tubes causes to increase in heat transfer coefficient (at least twice).

- Time required to produce steam is minutes.

- All of the security equipment and warning system are set on this system.

- Vertical boilers have the capability to run with national gas and gasoline.

- According gases from stack without applying generated temperature.

- Vertical boilers are designed and produced at operating pressures of 6,8,10 and 15 bar.

Vertical boiler controller equipment:

- Gas burner flame

- Water surface controller

- Pressure controller

- Feed water pump

- Water surface indicator

- Steam exit valve

- Discharge valve

- Water input valve

- Relief valve

- Manometer

- Smoke thermostat

- Distribution panel