Three Pass Hot Water Boiler

Advantages and Features

- Production in Accordance with European Standards

- Ease of Maintenance

- Possibility to Use Any Standard Torch

- Lowest Pressure Drop in Combustion Chamber

- The Highest Quality of Welding and Integrity

- High Thermal Efficiency Up to 92%

- High Thermal Shock Resistance

The design of these boilers is based on the maximum pressure

The required electricity for the initiation of boiler is three phase (50Hz, 380V).

Energy consumption in these boilers is 15% lesser than two passes water boilers.

General Specifications

Capacity

80,000-15,000,000 kcal/hr

Work Pressure

3-25 bar

Designing

EN 12953

Fuel

Gas, Gasoline, Solid Fuels

Power Consumed

50 Hz - 380 V

Product Introduction

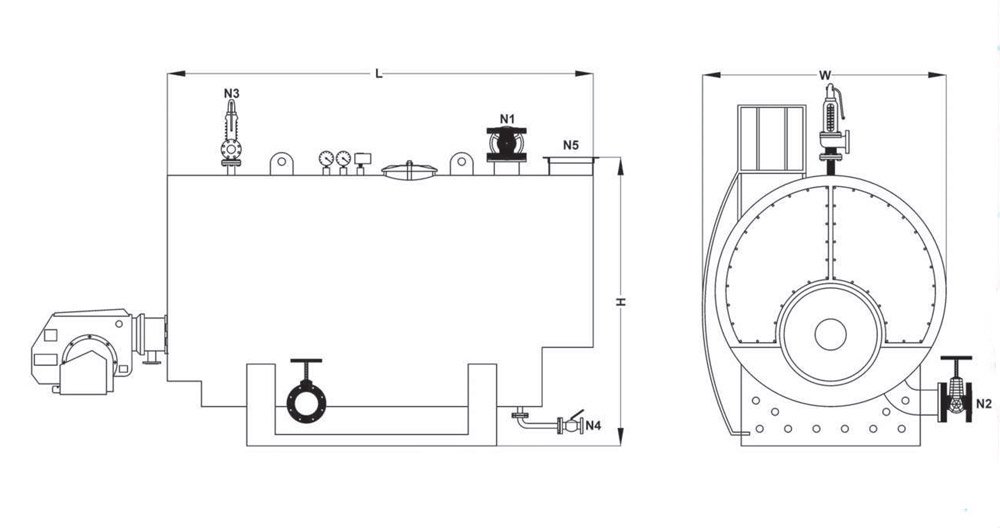

These boilers with the capacity of 80.000-15.000.000 kcal/hr operate at different operating pressures between 3-25 bars. The design of these boilers in capacities larger than 875.000 kcal/hr is firetube, steel, horizontal, three passes and wetback. For capacities smaller than 875.000 kcal/hr the boiler is semi-wetback.

In this design, the main furnace is eccentric and set at the bottom of the vertical axis of the boiler. The secondary furnace is set at the end of the boiler and makes its back region completely wet. In addition, it has a significant effect on turbulence and does not need incombustible materials and Chinese brick at the end of the boiler. High cost and longtime maintenance are not required. Therefore, efficiency and life span of the system will increase.

Hot water boilers of Daboo-Sanat are designed and produced based on BS2790, EN12953 European standards and, ISIR4231 , ISIR7911 national standards. All of the production steps are investigated and inspected by an Iranian Industrial Research and Standard Agency and, an Iranian standard and Quality Control Agency. These boilers have capability to run with all kinds of fuels (gas, liquid or solid fuels). Steel used for pressurized and unpressurized regions is DIN 17155 – 17MN4 and EN 1025 – S235JR, respectively. Heat transfer tubes are DIN 17175 – ST35.8 produced by high-accredited European companies.

Welding of pressurized region is SAW approach and done by boom and column machine and tanks operator positioner automatically, which provides high quality weld and integrity. For welding unpressurized regions and weld root, SWAW approach is adopted. In addition, for manual welding, E7018, E701 O electrodes in accordance with PQR and WPS are used. All of hot water boiler welding lines are tested based on standards mentioned under the supervision of an Iranian standard and quality control agency. These tests are include NOT consists of VT, PT, UT, RT. All of the welders are examined based on EN287 test and have a welding license from high-accredited inspection centers. They are under the supervision of Quality Control Department of the factory.

Hydrostatic tests at the pressure of 1.5 times as much as design pressure, with water at the low temperature of 7°C for about an hour, are investigated. Quality Control inspector inspects these tests.

Insulation and door fireproofing are done by ceramic fiber with 128 kg/m3 density through lingering and bookish approach. By adopting this approach, not only does it prevent from energy loss and observe obligations of NFPA 85 & 86 standards, but also it is resistant against thermal shock and does not require log time primary and maintenance. Insulation of boiler’s body is done by ceramic wool with 128 kg/m3 and 96 kg/m3 density and temperature tolerance of 1260°C with thickness of 2 inch and 3 inch (according to operation pressure and temperature).

Furthermore, insulation material fixer is colorful galvanize, aluminum and, stainless steel. This cover is set on the insulation layer so that there is no space between them and the maximum temperature difference between bodies and ambient is 15°C.

FEATURES:

- Handholes and Manholes those are set in boilers, create an opportunity to have an easy access to the tubes areas and furnace which simplifies descaling and maintenance. For simplifying services, inspections and maintenance, furnaces and heat transfer tubes are designed so that fume chamber and furnace are completely independent of each other.

- Because of having a wetback design, the maximum required distance in the fume cabin at the back of the boiler, is 1000mm.

- The design of these boilers is based on the maximum pressure, which is 1.1 times as much as operating pressure. Boiler at the pressure of 1.5 times bigger in comparison to the design pressure is investigated under hydrostatic test with water at the least temperature of 7 0C.

- The required electricity for the initiation of boiler is three phase (50Hz, 380V).

- This kind of boiler is designed to work at the least possible pressure loss in combustion chamber so any type of standard burner can be utilized in order to run it.

- Economizers, recuperators and turbulators are some examples of energy consumption reducer systems which are implemented according to the capacity and operation pressure of system, and economical issues.

- Energy consumption in these boilers is 15% lesser than two passes water boilers. So, the excess purchasing cost will be compensate very soon.

- Thermal efficiency of 89% is guaranteed for these boilers. By installing energy consumption reducer systems, thermal efficiency of 92% could be achieved.