Thermal Water Desalination

Advantages and Features

- Low Power Consumption

- No Need for Seawater Pretreatment

- Adaptation to Different Conditions of Inlet Water

- Lower Maintenance Costs Than Other Methods

No need for seawater pretreatment

Low power consumption

Adaptation to different conditions of inlet water

General Specifications

Capacity

-

Work Pressure

-

Designing

-

Fuel

-

Power Consumed

-

Product Introduction

Daboo-Sanat is able to design Thermal Water Desalination, thanks to over 25 years of experience and know-how in designing and manufacturing all types of boilers, heat exchangers and pressure vessels.

MED Method:

The MED evaporator consists of several consecutive cells maintained at a decreasing level of pressure (and temperature) from the first (hot) to the last (cold). Each cell (also called effect) contains a horizontal tube bundle. The top of the bundle is sprayed with sea water make-up that flows down from tube to tube by gravity. Heating steam is introduced inside the tubes. Since tubes are cooled externally by make-up flow, steam condenses into distillate (fresh water) inside the tubes. The heat released by the condensation (latent heat) warms up the sea-water outside the tubes and partly evaporates it. Due to evaporation, sea water slightly concentrates when flowing down the bundle and gives brine at the bottom of the cell. The vapor raised by sea-water evaporation is at a lower temperature than heating steam. However, it can still be used as a heating medium for the next effect where the process repeats. In the last cell, the produced steam condenses in a conventional shell and tubes heat exchanger. This exchanger, called “distillate condenser” or “final condenser” is cooled by sea-water. At the outlet of the final condenser, part of the warmed sea-water is used as make-up of the unit, the other part is rejected to the sea. Brine and distillate are collected from cell to cell till the last one, where from they are extracted by centrifugal pumps.

MED-TVC Method:

Or how the efficiency of the plant is improved by addition of vapor thermocompressor?

The MED-TVC evaporator is basically an MED evaporator fitted with a thermocompressor. The purpose of the thermo compression of the vapor is to take advantage of the pressure of the available steam to enhance the units’ performance. The incoming steam, calledEmotive steam, is fed into the thermocompressor through a sonic nozzle. Its expansion will allow low pressure steam from a cell of the evaporator to be sucked out. Both steams will be mixed in the thermo compressor body. The mixture is then compressed to the pressure of the first bundle through a shock wave. The latent heat of the sucked vapor is thus recycled in the evaporator and is again available for desalination, leading to energy savings.

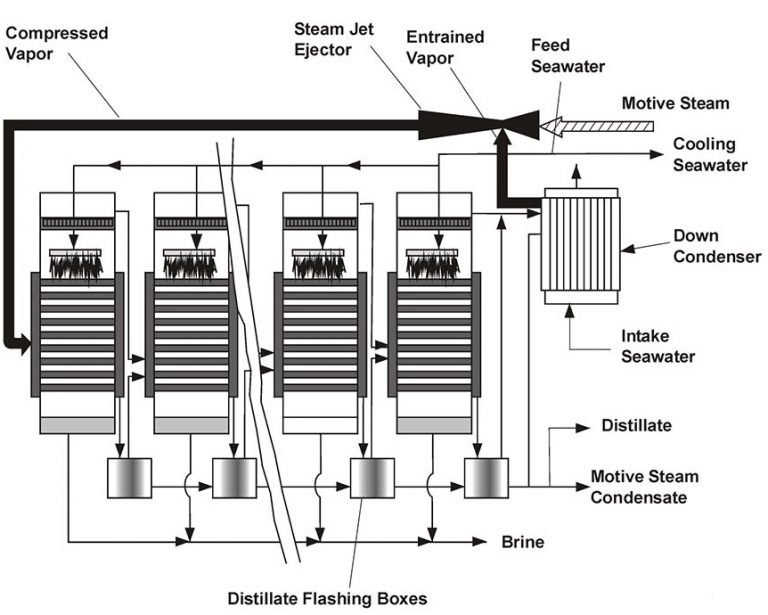

Multi Stage Flash:

The Multi Stage Flash (MSF) process is an innovative concept, where vapor formation takes place within the liquid bulk instead of the surface of hot tubes, the hot brine is allowed to flow freely and flash in a series of chambers. The brine circulation MSF process is the industry standard. The process elements are illustrated in the figure 2, where the flashing stages are divided among the heat recovery rejection sections. The system is driven by heating steam. Which increase the temperature of the brine recycle or feed seawater to the desired value in the brine heater. The hot brine flashes in the consecutive stages, where the brine recycle of the feed seawater flowing inside the condenser tubes recovers the latent heat of the formed vapor.

The MSF system does not include moving parts, other than conventional pumps. Construction of the MSF plants is simple and contains a small number of connection tubes, which limits leakage problems and simplifies maintenance works. In the light of the above, we strongly believe that the MSF system will remain the main desalination process, especially in the Middle East. This is due to the following facts:

- The conservative nature of the desalination owner

- The product is strategic life-supporting element

- Extensive experience in construction and operation

- Process reliability

- Limited experience, small database and unknown risks with new technologies