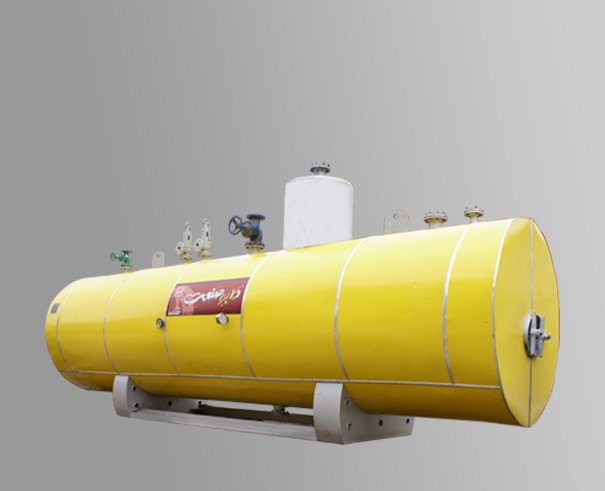

Steam Accumulator

Advantages and Features

- Providing Steady Steam at Low Rates

- Equipped with a Control System and a Safety Valve on it.

- Welding of All Areas Under Pressure Using the SAW Method.

Controller system and relief valve is set to safe accumulator

General Specifications

Capacity

1-50 m3

Work Pressure

6-25 bar

Designing

-

Fuel

-

Power Consumed

-

Product Introduction

Accumulator is a kind of storage tank which are constructed from steel used in pressurized tanks. These tanks are applied to store steam in order to use in peak hours. Steam generated in steam boiler enters accumulator and condense and the rest of steam fills the space above the water level. If steam is needed, steam valve, which is set on the top of the tank, should be opened. The reduction of pressure inside of the tank causes to evaporate the condensate water in accumulator and can be consumed.

Features:

- This system can be used in industries which need high steam flow rate in a short time and has capability to generate steam with steady flow rate at a short time.

- This system is designed and produced at different volume between 1 and 5O m3 and operation pressure between 6 and 25 bar.

- Controller system and relief valve is set to safe accumulator.

- Heads used are ellipsoidal head, elliptical head, and torispherical head based on ASME SEC VIII standard.

- For welding of the pressurized region SAW approach by boom and column machine which effects the best quality in product.

- For preventing energy loss from walls, body is covered with fiber ceramic with density of 128 kg/m3 and enough thickness. The insulation material preservatives is a colorful galvanized layer and aluminum.

- After all of welding process, heat treatment and normalization is done.