Punched Tray Deaerator

Advantages and Features

- Decreased Oxygen Dissolved in Water

- Decrease CO2 Free Measurable to Zero

- Full Efficiency in Valid Flows from 10% to 3% of Input Device

- Lowest Waste of Condensed Steam

- Minimum Height and Space Required by The Design

- Easy Installation

- Possibility to Install Complete Control Equipment

Complete operational efficiency in 3-10% of total flow rate

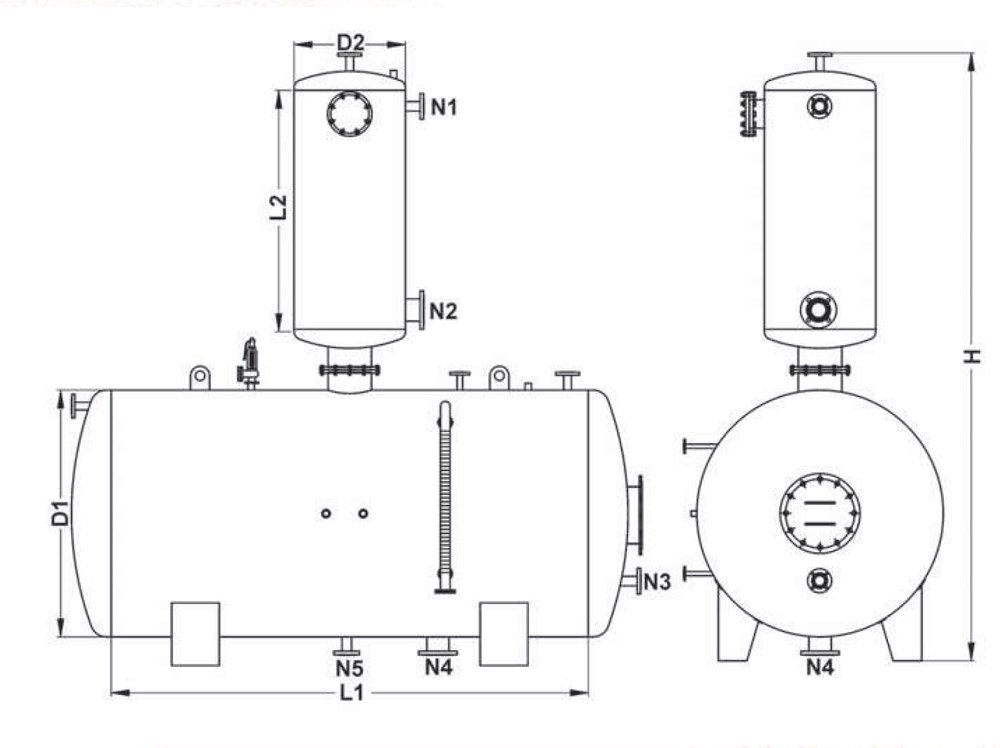

Dearator in form of horizontal with the capacity of 1-20 m3 /hr in three types based from based on costumer order are produced

General Specifications

Capacity

3,000-46,000 lb/hr

Work Pressure

3 bar

Designing

-

Fuel

-

Power Consumed

-

Product Introduction

Water is a good solvent for oxygen, carbon dioxide, nitrogen, and other gases. If water temperature becomes lower and water becomes more static, the possibility of gas compression will increase. In addition, as the temperature of water increases or water is circuited by pumps, gas solved in water will separate and lead to the corrosion of pipes and heating devices.

Furthermore, as the water temperature increases, corrosion will increase. Gas solved in water is one of the important reasons of corrosion in high temperature steam boilers. For this reason, the process of separation of non-condensable gases (oxygen and free carbon dioxide) solved in steam boiler feed water and condensate reverse prevents pipes, pumps, boilers and condensate return lines from corrosion. In addition, gas content in heating systems and gas compression in one point of system leads to the reduction of heat efficiency and in case of the sudden expansion, burst will occur in system. The use of chemical treatment and chemicals injection in system reduce losses to some extent. However, despite of being costly, this approach cannot solve the problem completely. Furthermore, because of chemical injection, PH in system will change which can cause another kind of corrosion in the heating devices. According to the reasons mentioned above, dearato r is used as a mechanical device to separate gases from feed water.

Dearator in form of horizontal with the capacity of 1-20 m3 /hr in three types based from based on costumer order are produced.

Features:

- The reduction of oxygen solved in water to lower than 0.005 cc/liter.

- The reduction of measurable free Co 2 to approximately zero.

- The increase of boiler feed water temperature to boiling point in order to prevent thermal shock in internal tubes of a boiler.

- The separation of air in water and the prevention of effects of air compression in one point especially, in boilers and heat transfer systems.

- Complete operational efficiency in 3-10% of total flow rate.

- The least amount of condensate steam losses and saving water and energy.

- Heating and full water bleeding by mixing water and steam in scrubber.

- The least height and space required because of appropriate design.

- Simplicity of installation.

- The possibility of installing full control equipment and even heat exchanger and lateral water pump, if necessary.