Heat Recovery Steam Generator

Advantages and Features

- Modular Package Design

- Factory Pre-Assembled and Tested Boiler

- Simple Fast and Safe Site Installation

- Quick Response of The Steam Output to Load/Heat

- Minimal Maintenance/Cost Effective Operation

Modular Package Design

Simple Fast and Safe Site Installation

Quick Response of The Steam Output to Load/Heat

General Specifications

Capacity

-

Work Pressure

-

Designing

-

Fuel

-

Power Consumed

-

Product Introduction

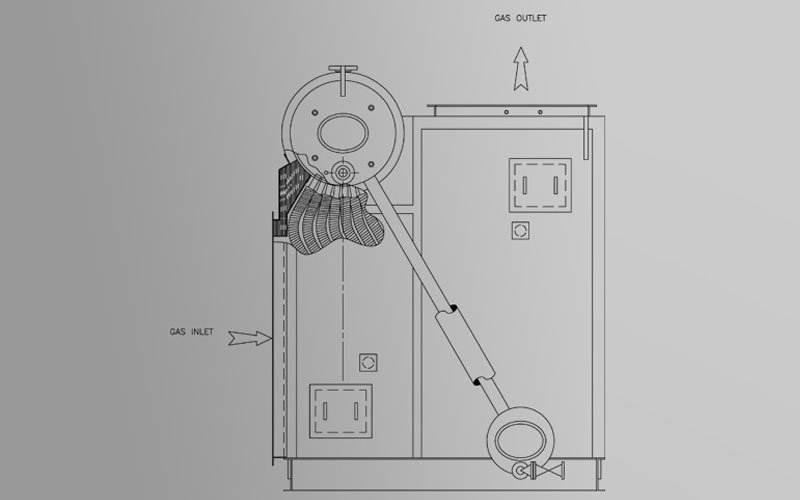

Daboo-Sanat‘s range of waste heat recovery steam generators are used for steam production or energy generation utilizing the waste heat from gas turbines, medium speed diesel engines or recovering the waste heat of some industrial processes. Daboo-Sanat can provide cost effective and reliable heat recovery boilers for combustion turbines. Daboo-Sanat has a board experience in heat and power systems, and is able to offer the best engineered solution for every application. Besides the capacity to offer in-house built boilers, Daboo-Sanat is able to develop all the mechanical and thermal system design, thanks to experience and know-how of the engineers in its staff. That allows Daboo-Sanat to offer complete turn-key solutions, from the gas turbine or engine outlet to the boiler exhaust stack.

The HRSG are supplied with regulation equipment, instruments, safeties, accessories, flue gas system, and whenever possible, the main pressure parts are delivered in a transportable package execution. Daboo-Sanat’s heat recovery steam boilers can feature an integrated control system for their easy management. The workstation allows to perform control and supervision. The most common design of Daboo-Sanat’s heat recovery steam generator is a water-tube, bi-drum, natural circulation structure.

The boiler design presents several advantages:

- Modular package design

- Factory pre-assembled and tested boiler

- Simple fast and safe site installation

- Quick response of the steam output to load/heat

- Minimal maintenance/cost effective operation