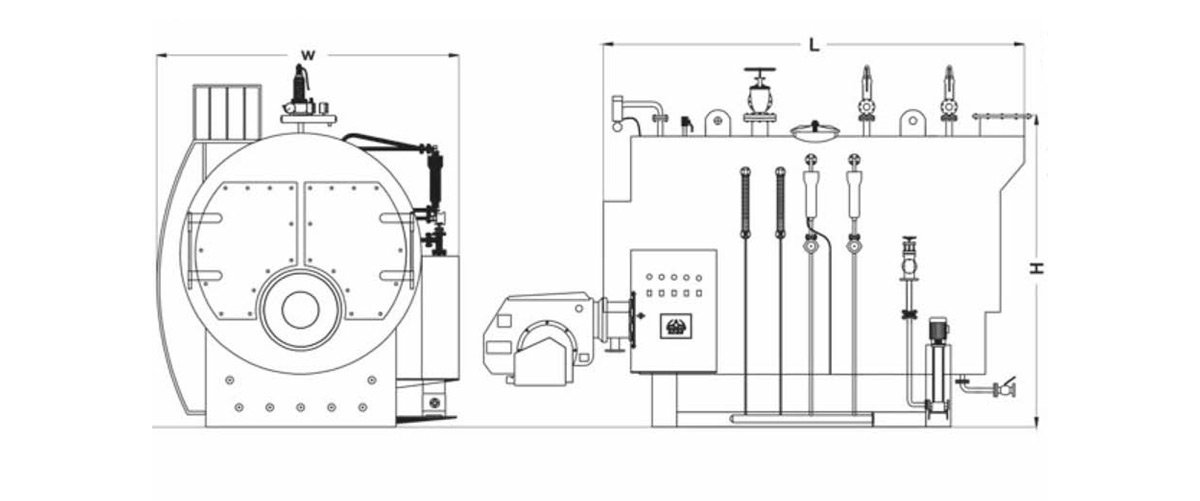

Firetube Horizontal Steam Boiler

Advantages and Features

- Optimum Consumption

- High Efficiency

- Simplicity of Primary and Maintenance

- Low Spatial Volume

- High Consistence

Because of having a wet back design, the maximum required distance in a fume cabin at the back of the boiler, is 1000mm.

The design of these boilers is based on the maximum pressure, which is 1.1 times as much as operation pressure.

High cost and longtime maintenance are not required.

General Specifications

Capacity

50 - 30000 kg/hr

Work Pressure

3-25 bar

Designing

EN 12953

Fuel

Gas, Gasoline, Solid Fuels

Power Consumed

50 Hz - 380 V

Product Introduction

These boilers with the capacity of 50 – 30000 kg/hr operate at different operation pressures between 3 – 25 bars. The design of boilers is fire tube, horizontal, three pass and wet back which have the ability to run with different kinds of fuel like gas, gasoline, oil and solid fuels. Optimum consumption, high efficiency, simplicity of primary and maintenance, low spatial volume and high consistence are some excellent characteristics of this product.

In this design, the main furnace is eccentric and set at the bottom of the vertical axis of the boiler. The secondary furnace is set at the end of the boiler and makes its back region completely wet. In addition, it has a significant effect on turbulence and does not need incombustible materials and Chinese brick at the end of the boiler. High cost and longtime maintenance are not required. Therefore, efficiency and life span of the system will increase. The terminal secondary furnace helps exclusion linear expansion of the main furnace and tube plate to the combustion chamber and increases radiation area. Steam boiler furnaces are introduced to the market in two different types: corrugated and HUP furnace which are selected based on operation conditions and operation pressure.

Steam boilers produced by Daboo-Sanat are designed based on EN 12953 standard and have a European validation certificate. Steel used in pressurized regions is A516G70 and DIN17155-17MN4 type, heat transfer tubes are fireproofing seam and DIN17175-ST35.8 type. Unpressurized regions are constructed from EN10025-S235JR.

The pressurized regions are welded by SAW approach automatically which result in the high quality welding and integrity. Heat transfer tubes are jointed to network by walls and welding. In addition, resistant tubes are jointed to network by electric arc welding based on WPS. Electrodes used for penetration and reinforcement welding are E 7010 and E 7018, which are based on WPS and PQR. AII of the weld beads are in accordance with national and international standards and are tested by inspectors of Iranian Standard and Research Agency. These tests include radiography, ultrasonic, penetrative materials and, hydrostatic, which are announced with technical certificate after the confirmation of quality inspections. All of the welders are examined based on EN287 test and have a welding license from high-accredited inspection centers. They are under the supervision of Quality Control Department of the Daboo-Sanat.

Each boiler is equipped by full automatic control panel, which is constructed from European high-grade components and includes security sensors.

Body insulation of boilers is made by incombustible ceramic fiber, which has capability to tolerate temperature until 1260°C. Furthermore, its resistance against humid penetration is far more than other insulations. Insulation is in forms of layer with thickness of 75mm from incombustible ceramic fiber with 128 kg/m3 density and heat transfer coefficient of 0.095-0.158 w/mk. Back and front doors and terminal tubes access of boiler have ceramic fiber insulation with 144 kg/m3 density and temperature tolerance of about 1400°C, which are insulted by spiral and bookish approaches. This approach not only has high resistance against thermal shock, but also causes to reduce door weight. One of the advantages of using ceramic fiber in insulation is the integrity of old insulation materials with primary substance in likely necessary maintenance. All of NFPA 85 & 86 standard obligations are considered.

Feature:

- Hand holes and manholes those are set in boilers, create an opportunity to have an easy access to the tubes’ areas and furnace which simplifies descaling and maintenance. For simplifying services, inspections and maintenance, furnaces and heat transfer tubes are designed so that fume chamber and furnace are completely independent from each other.

- Because of having a wet back design, the maximum required distance in a fume cabin at the back of the boiler, is 1000mm.

- The design of these boilers is based on the maximum pressure, which is 1.1 times as much as operation pressure. Boiler at the pressure of 1.5 times bigger in comparison to the design pressure is investigated under hydraulic test with water at the least temperature of 7 °C.

- The exit temperature of steam at the operation pressure of 10 bar, is 184 °C.

- The required electricity for the initiation of boiler is three phase (50 Hz, 380 V).

- This kind of boiler is designed to work at the least possible pressure loss in combustion chamber so any type of standard burner can be utilized in order to run it.

- Economizers, recuperators and turbulators are some examples of energy consumption reducer systems which are implemented according to the capacity and operation pressure of system, and economical issues.