Spiral Coil Supply

Advantages and Features

- Heat Transfer is Steady in The Whole of Volume Control

- Capacity of Hot Water Used Can Be Surveyed

- Capability to Set Up at Different Operation Pressure

- High Discharge Capacity

- Can Operate at The Pressure of 5, 8, 10 and 16 atm

Heat transfer is steady in the whole of volume control

Capability to set up at different operation pressure

General Specifications

Capacity

-

Work Pressure

5-8-10-16 bar

Designing

-

Fuel

-

Power Consumed

-

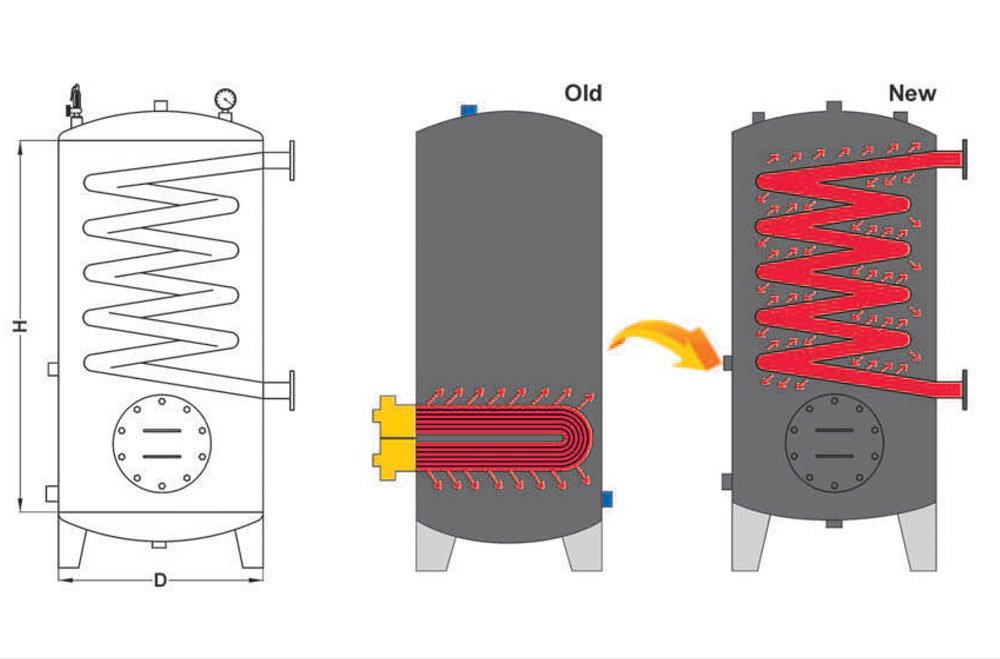

Product Introduction

Because of some problems associated with copper coil supply for high flow rate and capacity, Daboo-Sanat designed a new spiral coil supply. These heat exchangers are designed according to their application type and capacity in three different models. In these heat exchangers, tubes in forms of helical coil are set inside of the shell. The working fluid used (hot oil, steam or hot water) enters coli directly and distributes in all areas then leaves.

The main advantage of this design is the considerable increase of heat transfer.

Features:

- Heat transfer is steady in the whole of volume control because of the installation of coils from up to down,

- Capacity of hot water used can be surveyed,

- No sediment formation because of appropriate distance between coils and the distribution of coils,

- Because of high resistance of primary substances used in coils and cathodic protection, there is no need to replace coils,

- These heat exchangers have capability to set up at different operation pressure,

- These heat exchangers have high discharge capacity and their temperature difference with main heat exchanger is just 5°C,

- There is possibility to use stainless steel, copper and, carbon steel with galvanized cover or epoxy coils,

- These heat exchangers can operate at the pressure of 5, 8, 10 and 16 atm,

- There are a manhole and a discharge flange on supply to service and pickling,

- The steel used is galvanized (in case of consumer order, there is possibility to use stainless steel) and weld areas inside of a supply are covered with phosphate zinc and epoxy.