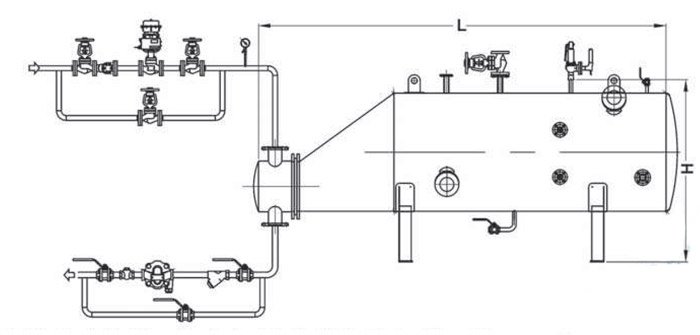

Clean Steam Generator

Advantages and Features

- All Design are According to EN285 Standard.

- All Clean Steam Wetted Parts in 316 Stainless Steel

- Fully Assembled Skid-Mounted

- Equipped with All Essential Safety Systems.

- The Unit is PLC Controlled

- Produces Steam to HTM2031 Standard.

All clean steam wetted parts in 316 stainless steel to avoid contamination.

Equipped with all essential safety systems.

The unit is PLC controlled with the generator having pressure and level control.

General Specifications

Capacity

250-3800 kg/hr

Work Pressure

Based on Temperature

Designing

EN 285

Fuel

Hot Water, Steam, Hot Oil

Power Consumed

50 Hz - 380 V

Product Introduction

Clean steam generators are used to produced pure and steam, free of any harmful substances and impurities. Applications for pure and clean steam are found in the food, cosmetic and pharmaceutical industries, as well as for sterilization and any direct steam heating processes where the demands on steam quality are very high.

Daboo-Sanat clean steam generators DS-HE-CS models are designed and built to produce steam to the HTM2031 standard, dependent upon feed water.

All clean steam wetted parts are in 316 stainless steel to avoid contamination.

Features:

- Produces clean steam for sterilization. Humidification and culinary or clean processes, from standard plant steam.

- All design and production functions are according to EN285 standard.

- All clean steam wetted parts in 316 stainless steel to avoid contamination.

- Fully assembled skid-mounted

- Equipped with all essential safety systems.

- The unit is PLC controlled with the generator having pressure and level control.

- Produces steam to HTM2031 standard.