Hydraulic Separator (Low Loss Header)

Advantages and Features

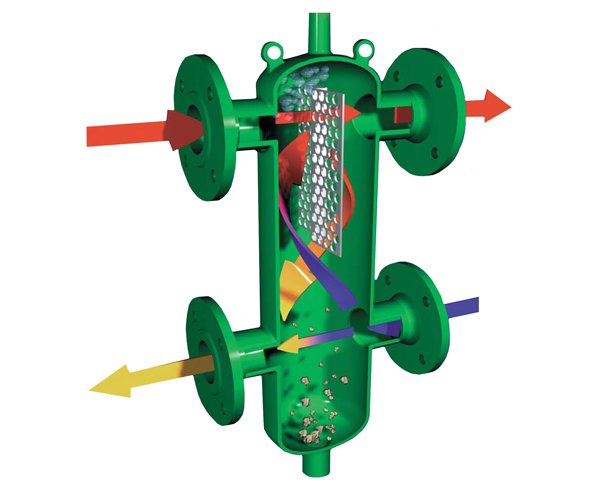

- Keeps Circuits Independent

- Automatically Removes The Circulating Air

- Separates and Collects Particles

Keeps circuits independent

Separates and collects particles

Automatically removes the circulating air

General Specifications

Capacity

-

Work Pressure

-

Designing

-

Fuel

-

Power Consumed

-

Product Introduction

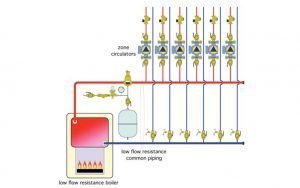

When a single system contains a primary production circuit, with its own pump, and a secondary user circuit, with one or more distribution pumps, operating conditions may arise in the system whereby the pumps interact, creating abnormal variations in circuit flow rates and pressures.

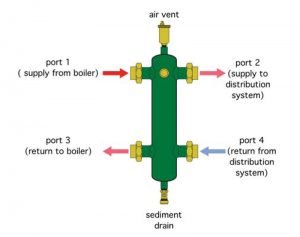

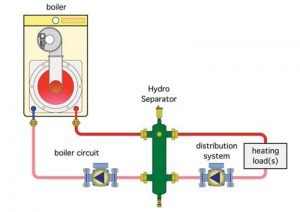

The hydraulic separator creates a zone with a low pressure loss, which enables the primary and secondary circuits connected to it to be hydraulically independent of each other; the flow in one circuit does not create a flow in the other if the pressure loss in the common section is negligible.

In this case, the flow rate in the respective circuits depends exclusively on the flow rate characteristics of the pumps, preventing reciprocal influence caused by connection in series. Therefore, using a device with these characteristics means that the flow in the secondary circuit only circulates when the relevant pump is on, permitting the system to meet the specific load requirements at that time.

When the secondary pump is off, there is no circulation in the secondary circuit; the whole flow rate produced by the primary pump is by-passed through the separator.

With the hydraulic separator, it is thus possible to have a production circuit with a constant flow rate and a distribution circuit with a variable flow rate; these operating conditions are typical of modern heating and air-conditioning systems.